A big part of the economic landscape of 2015 – and onwards - is the sharp fall in the price of oil, threatening continuing production in the North Sea, employment and state revenues. This will be the case for an unpredictable number of years but carries the possibility of being the end of the line for the North Sea as a producing industry.

Industry confidence is described as being at a six year low. Some informed predictions give the North Sea two decades to dead.

If and when that happens, oil and gas production in the North Sea will be replaced by a new industry there that will last for around 40 years and will have progressively marketable expertise and skills. This will be the decommissioning industry which will largely be based in Aberdeen and which will have entirely new challenges to confront and solutions to develop.

This industry is going to generate a new breed of vessels of various function, with heavy lifting a baseline task. It will secure long term employment and therefore earn for the state both income tax and corporation tax from the contractors. It will never generate the revenues that came from oil production in the good days but it will be a much more predictable earner.

Should multiple shut downs in the North Sea occur, that would trigger the start of the development of a serious decommissioning industry. No one will invest in working up the expensive and innovative technology needed or in commissioning infrastructure until there is an assured prospect of continuing work for it.

The price situation

In the last year, the steep fall in the industry benchmark price of a barrel of Brent crude – with a 40% plunge in six months from $115 a barrel in June 2015 to $60 a barrel in December 2014 [and to $56.42 a barrel at close of play on 2nd January 2015] – has been driven by a surplus of supply [which is not short term] and a weakening demand.

- There are 2 million barrels a day of surplus oil on the market.

- America is exporting large volumes of cheap surplus shale [tight] oil and gas.

- The Organisation of Petroleum Exporting Countries [OPEC], which traditionally controls the price of oil by stopping production to limit supply and drive up prices, has taken the unusual decision to continue to produce at the current low price levels – creating a glut in the market.

- OPEC has said it will not meet again until June 2015 to review the situation.

- China’s previously burgeoning market for oil has been dealing with economic setbacks and is buying less.

OPEC is testing America’s pockets as shale production is barely washing its face at the current price of Brent – although there is no sign of strain yet in the US shales sector. A former OPEC President told Sky News recently that OPEC used to be able to control the price of oil – but that the industry has changed and they can no longer do that. He described OPEC as now fighting to maintain its market share.

The glut on the market is not going to go away for some time. Part of the reason for this is the nature of shale oil production.

Unlike conventional gas and oil wells where, if you need to, you can, ‘turn the tap off” for a while, once you start to frack a well you have little economic choice but to carry on until you’ve emptied it. A shale well – tight oil – is usually wet. After fracking, the freed gas will keep rising – but if you stop producing, the well will fill with water. When you want to start up again later you will have to de-water the well. This is not a quick process, involves significant costs and is uneconomic when the price is low.

So America has carried on production until the shale wells on flow can be closed down for good – hence the surplus for export. Texas is also considering opening up new shale wells.

Generally speaking, over a limited period of downturn, operating companies will choose to continue producing on a cash balance – earning enough to pay their operational bills alone [but not depreciation] and accept the hit on profits. This is economically preferable to mothballing, where an estimated 70% of normal costs are still incurred but with no return – and with with added costs in restarting production. It also keeps a hefty percentage of employment going, with all of the skills retention involved.

But when the price of oil falls to the point where even that balance is unachievable, where they can’t earn enough to pay their operating bills, the decision is one of mothball or shut-down – and that is a decision absolutely germane to the situation in the North Sea today.

The economic impact of shut down

It is in the interests of the UK government to do what it affordably can to make the almost inevitable shut down in the North Sea as progressive as possible

For as long as operating companies of any size can be enabled to carry on producing at a cash balance level, at least there are jobs and those jobs yield income tax.

Shut down is a triple whammy on state revenues:

- loss of corporation taxes on production profits and on supply side profits – expert estimates from industry body, Oil & Gas UK, are that tax revenues from the industry for 2014 will fall to around £3 billion – from £12billion in 2011.

- loss of income tax with job losses;

- the need to support large numbers of suddenly unemployed people with no immediate prospect of alternative work.

The more gradually shut-down happens the more the economic and social shocks of it are smoothed.

The trade unions are already very concerned about the impact on job losses of the possible departure of Apache. BP, the biggest North Sea employer is known to be looking at job cuts, as are several other players. Shell is selling its share of the Sean field in the southern North Sea.

It is not hard to imagine the impact on the economy of sudden large scale shut-downs in the North Sea industry. The loss of projected tax revenues from the North Sea.

Ian Wood has said that the UK government should ‘fast track’ planned tax incentives to keep the industry operating in the North Sea – but there is no sign of that sort of urgent response from government. George Osborne’s latest budget statement proposed to drop 2% from the 32% Supplementary Corporation Tax – supplementary to the basic 30% rate of Corporation Tax for exploration – with Treasury Secretary Danny Alexander saying that tax cuts – via the new Investment Allowance – would come ‘when they are affordable’ and would be ‘introduced over time’.

Major companies are arguably capable of absorbing the hit of continuing to produce for 1-2 years on a cash balance operation – but they will only do so if they are confident that at the end of that time there is an assured price recovery to make that pain worth taking. Some already feel that the pain is too great.

The oil & gas industry modus operandi

The oil and gas industry is largely private sector, funded by shareholders with the core focus of the business being to return the best possible dividend on that investment. It is a high risk industry – any exploration has no more than a 20% chance of being worthwhile.

The costs of production infrastructure are astronomical. BG Norge commissioned a newbuild FPSO [Floating Platform, Storage and Offloading vessel] from Samsung Heavy Industries in South Korea, with a project cost of around $1 billion. It is due to start operating later this month in Norway’s North Sea Knarr field.

A newbuild drill rig for the North Sea will cost $0.5 Billion, with a separate accommodation rig [Floatel] and a separate admin rig to be added. At the moment a North Sea FPSO costs around $100,000 a day with no payback where it is delayed by weather from going onstream.

The 2013 cost estimates for Shell’s gigantic Prelude, the world’s first FLNG [Floating Liquefied Natural Gas] platform and the largest offshore facility ever built [also by Samsung in South Korea] – were $10.8 – $12.6 Billion.

The tax regime under which this industry operates is critical, not only to profitability but to forward planning and investment. The affordability of investment in more efficient technologies or in new exploration and production is governed by the tax regime of the area of operation. The UK government takes 81% of profits in tax. The remaining 19% has to pay shareholders, cover depreciation and maintenance and decommissioning costs.

Profit margins could not be more critical in an industry where the scale of everything – infrastructure, operations, logistics, costs, profits and losses – are in numbers the rest of us have to take time to figure out.

The North Sea situation

The initial physical pressure behind extraction creates a profile of production from any well that is an initial spike or high plateau followed by a pronounced fall and a long tail away. The existing North Sea assets are now in tail away. There are unswept assets and there are new reserves but what’s left is modest, usually heavy crude [thick and sticky, not flowing] and in deep and difficult waters – all making it expensive to get out.

When the price of oil is high enough, it can be worth the investment in extraction and production costs. – but when the price of oil is low, extraction from the North Sea is uneconomic.

North Sea reserves are also relatively insignificant. There was a recent find in the Autumn of 2014 estimated at 50 million barrels. This caused much excitement in Scotland but the reality is a telling industry comparison – a field in Brazil is estimated to produce half a million barrels a day when it comes onstream.

In the North Sea. the best fields are Buzzard – recognised as the best find for 25 years; the Elgin Franklin; and the J Block wells. BP”s Clair Ridge field, west of Shetland, is decent field but heavy crude, expensive to get out.

Statoil has set up in Aberdeen to operate the Mariner Field. Mariner’s oil is very heavy crude. To date it has not been worth trying to extract this because it was too thick to flow. But now additives can be used to encourage flow and that is Statoil’s intention – but the use of these additives means more processes and more materials – and higher costs. With the current low oil price knocking the business case for production from Mariner at the moment, Statoil will wait and see – or go away and take a decision on what to do as and when the picture is different.

Apache – which did massive and enabling recovery work in new exploration, recommissioning and project management in the Forties Field area – with an operating efficiency of over 90% compared to an industry average of 60%, has, since early October 2014 – when Brent was $94 a barrel – been considering its option on a retreat from the North Sea. Apache is the third largest North Sea oil producer, after BP and Shell.

It is said authoritatively that in reality today, everything in the North Sea is for sale.

The following factors dictate this position:

- The price of Brent is low and falling, Yesterday, Friday 2nd January, it finished at $56.42 a barrel, having earlier in the day touched a post-2009 low of $55.48. Morgan Stanley have predicted a fall to $43 a barrel in 2015. The comparison is Brent’s averaging around $110 a barrel between 2011 and 2013.

- The existing North Sea Fields are largely post-mature assets.

- The cost of extraction of unswept assets and new reserves and of developing new plays from the North Sea is high and not economic at the current price per barrel.

The expectation for 2015 is that some fields will shut down; some new projects will be on go slow; and some planned new projects will not start. It is not economically viable in the present circumstances to go ahead with new production.

Consultants Wood Mackenzie have estimated that, even if the price of a barrel of Brent Crude held at $60 to $70 [which would be against predictions of a further fall], at least 85% – or $27 billion worth – of planned new British offshore oil and gas development could be dropped, with a potentially huge threat to jobs; and that many older North Sea oil and gas fields could begin losing money, potentially causing them to be shut down.

How realistic is it to assume that production in the North Sea can carry on?

There have been expert predictions that no new investment will happen for the time being; and that, with OPEC not even scheduled to meet again until June, there is nothing to steady the price of oil.

In 2014 only 28 wells were drilled – and of these only 13 were drilling for new finds. The other 15 were drilled to evaluate the size of existing finds. This is the lowest level of drilling since the industry began in the mid-1960s.

Losses of jobs and skills – and the hit on the secondary services sector

Ian Wood of the influential services supplier, the Wood Group – which has made two recent acquisitions to increase its access to American shale producers – has said:

‘I don’t believe there’s an operator anywhere in the North Sea right now not going through the their people numbers and looking at what they can do to cut costs for 2015′.

It is anticipated that around 10% of the 375,000 jobs in the production and supply sides of the industry will be lost between 2014 and 2019. This was the conclusion of the report, Fuelling the Next Generation, from the collective of industry body, Oil & Gas UK, OPITO [Offshore Petroleum Industry Training Organization] and the UK government’s Department for Business, Innovation and Skills. But this report was issued in May 2014, before the price of Brent fell 40% from its high of $115 a barrel in June to $56.42 yesterday. The prospects may now be even more depressing.

The weight of job losses in the primary producing sector is said to be targeted on head office and back office staff; and not on frontline production staff. This may indicate that the pragmatic oil producers are taking advantage of the current price crisis to get themselves down to leaner operations with less public resistance than they might otherwise meet.

When you cut jobs and lose people, when you cut services and squeeze the costs of services, you lose expertise, high level skills and industrial capacity that, after a 1-2 year retraction, are likely to be irrecoverable. This process of dereliction affects both the primary producing and the secondary supply sides. It is worth noting that the skills shortages of which the industry had repeatedly complained are markedly lower than they were 12-18 months ago, with the progressive slow down in North Sea activity.

The much more vulnerable services supply sector includes engineering, fabrication, equipment design and manufacture, accountancy, transport, food supply, catering. The impact of these losses on capability and on the economy through the loss of corporate and personal tax revenues they generate is accelerated by the loss to the wider economy of a substantial volume of disposable income.

North Sea shut downs, asset sales and consequences

While it is known that today ‘everything in the North Sea is for sale’, it is not a sellers market for such assets. Buyers will tend to be small lean companies, taking a punt on being able to get enough profit out of a post-mature asset to be worthwhile in their own terms. But they are going to find finance hard to come by – and expensive.

Where the price of Brent falls below being able to pay asset operating costs out of sales, operating companies will have a decision to make. If they mothball a production unit, it will cost them around 70% of normal operating costs – but with no return. In the current uncertain climate of the industry into the immediate future, with the endemic economic demands of North Sea production – and with further falls in price anticipated – the business case for simply closing down production is compelling.

If you close down, your situation is like continuing to own an unoccupied and untended property. You still have some unavoidable basic costs to pay, but for as long as you continue to own it you are looking at a physically declining asset which will be substantially expensive to regenerate later.

Most of the infrastructure in the North Sea is already beyond its design date and is overdue decommissioning. Production from the North Sea will always be relatively expensive compared to assets in other places. This means that the reactivation of shut down assets there will be cost heavy – for what reward? A modest production volume at a less economic return than you could get in assets elsewhere? Why would you do that?

The obvious probability is that any North Sea assets shut down in the current crisis will not be reopened – and will not be intended to reopen.

Decommissioning

Permanent shut down means almost immediate entry to decommissioning – the costs of which will initially be high as the technology is immature.

Larger companies selling an asset to a smaller one require bonds to be lodged to insure them against the failure of the incoming operator, who would then be unable to pay for the obligation to decommission. This requirement for these protective bonds is because the government will legally pursue decommissioning responsibilities down the chain of owners of an asset until, if necessary, it comes to the original owner of a field.

All operating companies in the North Sea are already paring costs to a minimum in order to continue to produce. This austerity accounts for reliable reports of the position with one smaller operator where workers are said to be bringing in their own tea bags.

While the government ‘subsidises’ decommissioning to a degree, this is done in a way which underlines that it is no cosy arrangement. The Government will carry 50% of the cost of decommissioning – by returning a sum of that value to the owner concerned – from tax revenues already paid.

In the case of a medium to large operator, decommissioning of a newly purchased but failed asset may be set against the tax to be paid against the earnings of another asset.

But a new small operating company may have an inadequate tax payment record to cover any or all of 50% of decommissioning costs. Such an owner may have no other asset against whose due tax revenues decommissioning costs for a closing asset might be set. So this is when the government goes after the last owner of the asset – and the last before that etc – until responsibility for decommissioning may be achievably enforced.

The positive question

When the USA embraced fracking with enthusiasm, the country reindustrialised on the strength of cheap energy.

With the price of oil and gas as low as it is, with the UK itself in a position to frack and with Yorkshire in particular the possessor of major shales, is this country not looking at the reindustrialisation that could be transformational for our economy and for our services-dependent culture?

Shale gas could be fed directly into the national grid, with several wells tied back to a hub and fed in from there – or directly fuel a power station.

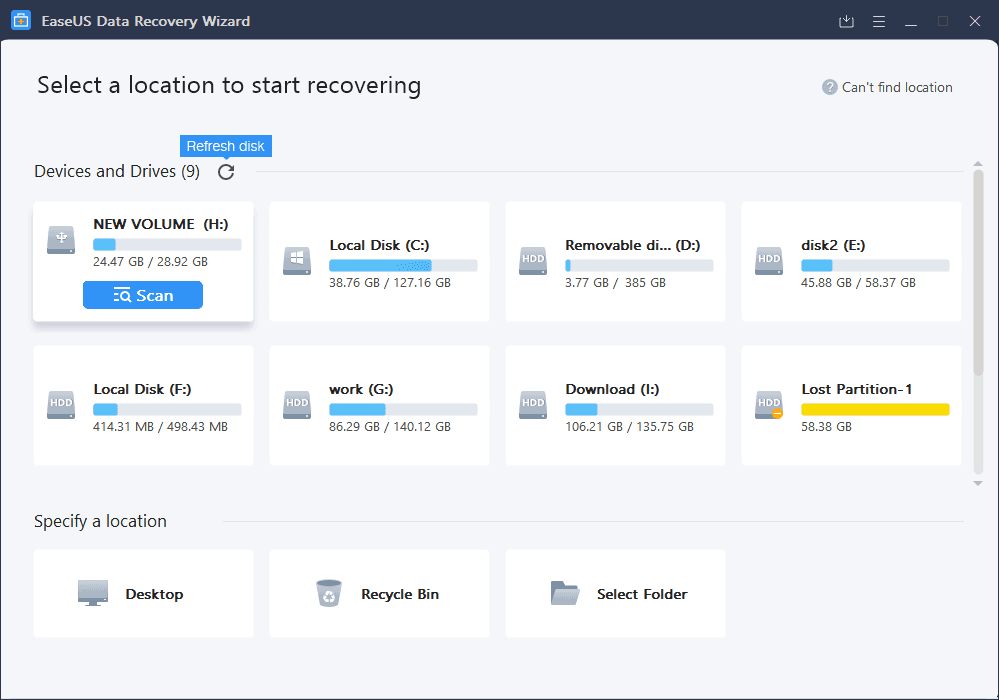

Note: The image at the top of this article is by Jaybear and is in the Public Domain. The numbered items are: 1, 2) conventional fixed platforms; 3) compliant tower; 4, 5) vertically moored tension leg and mini-tension leg platform; 6) spar; 7,8) semi-submersibles; 9) floating production, storage, and offloading facility; 10) sub-sea completion and tie-back to host facility.